SUSTAINABILITY

With responsible technology, we give our Earth another chance

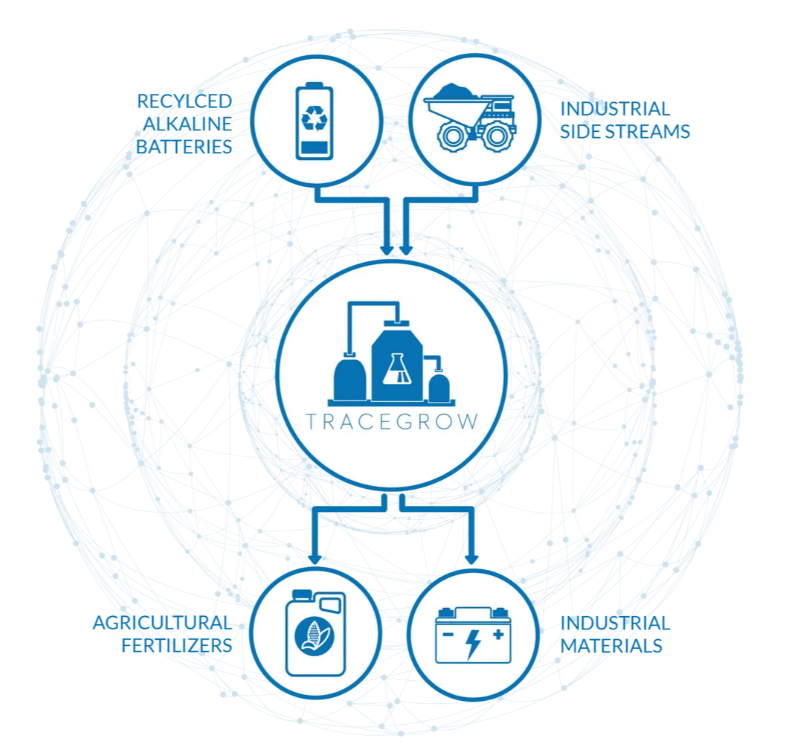

We respect our planet's valuable raw materials, and that's why we clean and return them for reuse. This is made possible through our unique RETRACER recycling technology.

Our groundbreaking technology provides tangible solutions for recycling depleting raw materials, reducing corporate emissions, and achieving sustainability goals.

Our aim is to secure the vitality of our planet with sustainable products.

Read more about our sustainability initiatives.

>> Our unique technology transforms spent alkaline batteries into circular economy products

Sustainability in Agriculture

Luomuhyväksytyt hivenlannoitteemme pienentävät maatalouden hiilijalanjälkeä ja vähentävät ympäristökuormaa. Ne lisäävät satoa ja viljelystä tulee taloudellisempaa, sekä tehokkaampaa.

Sustainability Across Different Sectors

Through our technology, industrial companies can efficiently process their byproducts, thereby reducing their carbon footprint, while also gaining access to valuable recycled raw materials.

Our Technology

Our groundbreaking technology transforms spent alkaline batteries into circular economy products.

Our RETRACER technology and groundbreaking process facilitate the recovery of valuable trace elements, such as manganese and zinc, from recycled batteries and industrial side streams. From these reclaimed elements, we manufacture low-carbon footprint foliar fertilisers for agriculture and raw materials for industrial use. Our production has minimal biodiversity impact.

Our patented, eco-friendly technology boasts versatile applications and can be tailored to sectors such as agriculture and various industries, making it suitable for global scalability. Our technology has garnered numerous accolades, including the prestigious Circwaste Award from the Finnish Environment Institute.

-

Button

Click to enlarge the image.

Our production plant in Finland has the capacity to produce up to 10 million liters of liquid fertilizers for agriculture annually, with minimal emissions. Through our technology, we recover 90% of raw materials from alkaline batteries, compared to traditional battery recycling methods that only recover 50%.

At our production plant:

- No wastewater is generated.

- No smoke or emissions are produced, and there is no smokestack in our facility.

- Our energy consumption is minimal because our process operates at room temperature.

- We are certified according to the highest recycling material standards in the EU.

- Our product manufacturing meets ISO 9001 and 14001 standards."

Emission Reduction

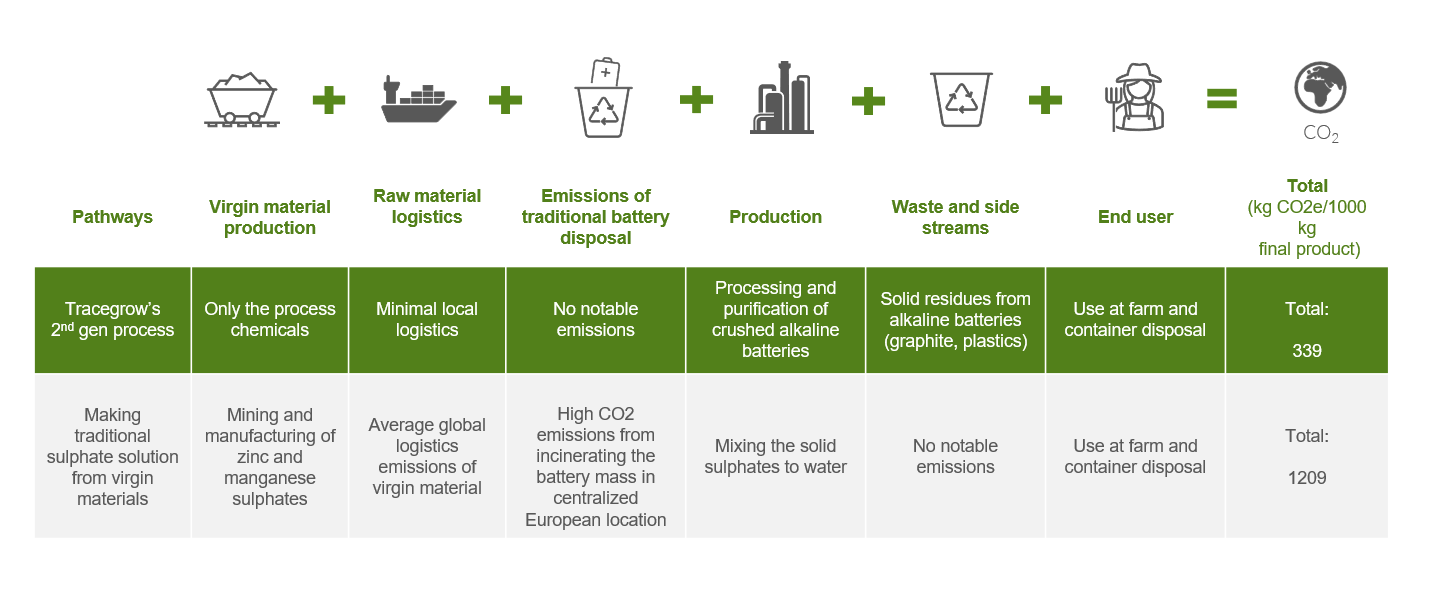

A 70% reduction in CO2 emissions

Compared to traditional practices, our process achieves an impressive 70% reduction in overall emissions. These practices involve mining virgin raw materials from distant sources, transporting them over long distances, and recycling used alkaline batteries through conventional methods.

-

Button

Click to enlarge the image.

Lifecycle Analysis

Lifecycle analysis reveals our strengths

Lifecycle analysis reveals why our process generates significantly fewer emissions compared to traditional methods. In our value chain, we are not dependent on mining trace elements or transporting raw materials over long distances. One key advantage of our process is regional production, which substantially reduces emissions related to logistics. The majority of our emissions occur at our production plant during the processing of recycled raw materials using our RETRACE technology.

-

Button

Click to enlarge the image.

Why Partner with Us?

Efficient Byproduct Management and Waste Reduction:

We effectively manage byproducts and sidestreams, leading to waste reduction.

Significant Carbon Footprint Reduction:

Achieve up to a 70% reduction in carbon footprint compared to similar products and components.

Access to Valuable Recycled Raw Materials:

Gain access to valuable recycled raw materials, aiding in meeting future recycling requirements and stricter emission limits.

Recycling mined elements:

We give once-mined but valuable elements a new lease of life.

Predictable Price Development:

Enjoy the advantage of predictable price development.

Materials from European Recycling and Production:

Our materials, sourced from European recycling and production, ensure well-known and safe working conditions

To reserve a one-on-one meeting with our team,

contact us directly and book a appointment

Yes, please, I would like to subscribe to the newsletter.

Join our newsletter to stay updated on agricultural news and Tracegrow events.

Lähetä meille viesti!

We will get back to you as soon as possible.

Please try again later.

About Tracegrow

We recover valuable trace elements from recyclable materials and industrial side streams.

©TRACEGROW 2024